BTA International GmbH

Booth number: B5/503/6

bta-international.de/en/

About us

Founded 1984, BTA was one of the pioneers in the anaerobic digestion of organic residues.

Today, with fourty years of experience, our company is one of the leading specialist for the wet-mechanical (pre-)treatment of all types of organic waste up to household waste as well as the further processing of the purified organic suspension.

With the BTA® Process, which was developed in the late 80’s and since then continuously has been further developed, we have a unique technological platform for anaerobic digestion plants, ensuring the reliable and successful operation of these facilities. The first industrial waste treatment plants using the BTA® process were already built in the 1990s and are still successfully operating for the most part. Since then, over 55 plants world-wide have been designed and constructed according to the BTA® Process or with key components from the wet mechanical pre-treatment with a total capacity of over 2 million tons per year.

In function of the project, BTA can act as technological partner, turnkey supplier for individual process steps or full anaerobic digestion plants.

We have a comprehensive and long-standing engineering and project management expertise. From the first phases of project engineering to plant realisation, commissioning and after sales service, we work closely with our customers or project partners to offer the best solutions for the specific projects.

Address

Hauptplatz 12

85276 Pfaffenhofen

Germany

E-mail: n.drogosch@bta-international.de

Phone: +49 8441 8086100

Internet: www.bta-international.de/en/

Via di Francia 54R

16149 Genova

Italy

E-mail: bta@bta-italia.it

Phone: +39 010 0987900

Internet: www.bta-international.de/it/

Contact person:

Stephan Schulte

E-mail: s.schulte@bta-international.de

Phone: +49 0516 4922812

Products & Services

BTA® Process - Wet Digestion Technology with Manifold Applications

Due to its high flexibility for substrates with a wide range of TS-contents as well as different impurities contents, and its high efficiency in separating these impurities upfront the anaerobic digestion, the BTA® Process has multiple applications:

MBT plants for Municipal Solid Waste

Methanization plants for biowaste, food waste and/or commercial waste

Co-digestion with agricultural substrates

Co-digestion with sewage sludge

Refurbishment of existing plants.

The BTA® Process ensures operational security, wide recovery of digestible organics, high biogas yield, and minimal impurities content in the digestate.

BTA International’s strengths are more than 40 years of experience in the design and execution of methanization plants, in-house development work, and over 50 plants worldwide with either parts of or the entire BTA® process.

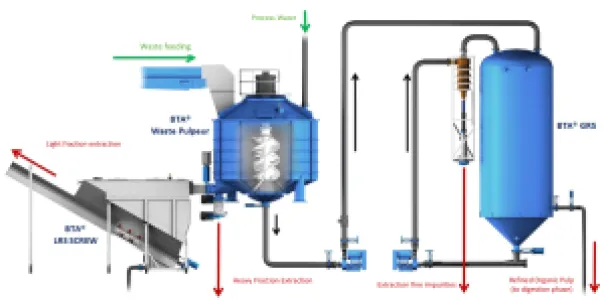

BTA® Hydromechanical Pre-treatment

BTA® Hydromechanical Pre-Treatment, the original of wet-mechanical waste processing, enables the efficient separation of impurities as well as the complete transfer of fermentable organic components into an organic suspension.

BTA® Compact Series

The BTA® Compact Series is a high-end, compact and cost optimized organic waste pre-treatment line, for small to middle sized projects (6 000 tons - 12 000 tons/y)

Anaerobic digestion

The purified biosuspension is temporarily stored in a suspension tank. It decouples the treatment section from the actual fermentation so that the latter can take place independently of the working rhythms of the waste reception.

The organic suspension is fermented in fully mixed fermenters, usually single-stage and mesophilic fermentation at 35 - 38 °C. The design of the fermenter and its mode of operation depend on the type of feedstock and the project-specific requirements for microbiological degradation and biogas yield. The design of the fermenter and its mode of operation depend on the type of feedstock and the project-specific requirements for microbiological degradation and biogas yield.

Plant extensions and refurbishments

BTA has been awarded with the contract to expand the AD facility Granollers (Spain). After Castelleone (ITA) and Valorlis (POR), Granollers marks BTAs 3rd AD plant expansion in 2023!

-thumb.webp)

-thumb.webp)